Application: sawdust, wood chips, wood flour, wood shavings, etc.

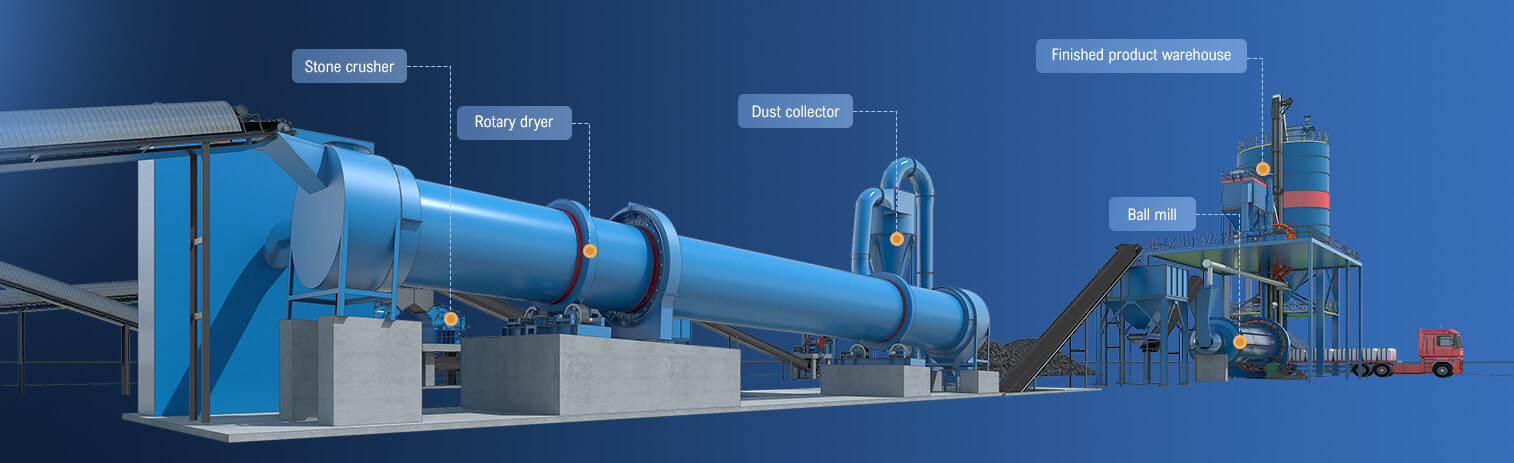

The sawdust dryer uses a screw conveyor to continuously add the wet sawdust into the drying tube. In the transportation and dispersion of the high-speed hot gas flow, the water in the wet material is evaporated to obtain a powdery or granular dry product. The dryer equipment has strong adaptability to materials and can dry various materials, and the equipment operation is simple and reliable. According to different processing materials, it can be divided into coal dryer, sand dryer, slag dryer, gypsum dryer, lignite dryer, sawdust dryer, etc. Users can choose the machine according to their own needs.

FTM dryers can support multiple heat sources and are easy to switch. The choice of heat source determines the operating cost of the equipment, so the choice of heat source needs to consider safety, environmental protection, material quality requirements, etc. The more common heat sources are mainly divided into three categories: solid fuel, gas fuel, and liquid fuel.

The thermal efficiency is 80% to 90%. The new internal structure strengthens heat conduction of dispersed materials, and eliminates the sticking phenomenon of the inner wall of the cylinder.

Since the heating mode is easy to control, the temperature inside the cylinder and the heat transfer rate of the partition wall can be kept relatively stable.

The cylinder of the dryer is made of steel material, which has the characteristics of high hardness and high toughness.

The dryer system has good sealing performance, and is equipped with a complete dust removal device, with little dust spillage and a good operating environment.

Our drying equipment has been exported to more than 160 countries, such as Indonesia, Malaysia, Ethiopia, Nigeria, South Africa, Pakistan, Egypt, etc. The following is the site of our customer's drying machine.

Rotary Dryer

Indirect heat transfer dryer

| Spec./m | Shell Cubage | Capacity(t/h) | Installation(%) | Highest Inlet Air Temperature(℃) |

Main Motor |

| Ø1.2×8 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 |

| Ø1.2 ×10 | 11.3 | 2.4-3 | 3-5 | 700-800 | 7.5 |

| Ø 1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 |

| Ø 1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 |

| Ø1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 |

| Ø 1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 |

| Ø 1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 |

| Ø 2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 |

| Ø 2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 |

| Ø 2.2×16 | 60.8 | 13-16.2 | 3-5 | 700-800 | 22 |

| Ø 2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 |

| Ø 2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 |

| Ø 2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 |

| Ø 2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 |

| Ø 2.6×24 | 127.4 | 27.2-34 | 3-5 | 700-800 | 55 |

| Ø 3×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 |

| Ø 3×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 |

| Ø 3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 |

| Ø 3.6×28 | 285 | 60.8-76 | 3-5 | 700-800 | 160 |

| Spec./m | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Ø 1.2×8 | 1.9-2.4 | 700-800 |

| Ø1.2 ×10 | 2.4-3 | 700-800 |

| Ø 1.5×12 | 4.5-5.7 | 700-800 |

| Ø 1.5×14 | 5.3-6.6 | 700-800 |

| Ø1.5×15 | 5.7-7.1 | 700-800 |

| Ø 1.8×12 | 6.5-8.1 | 700-800 |

| Ø 1.8×14 | 7.6-9.5 | 700-800 |

| Ø 2.2×12 | 9.7-12.2 | 700-800 |

| Ø 2.2×14 | 11.4-14.2 | 700-800 |

| Ø 2.2×16 | 13-16.2 | 700-800 |

| Ø 2.4×14 | 13.5-16.9 | 700-800 |

| Ø 2.4×18 | 17.4-21.7 | 700-800 |

| Ø 2.4×20 | 19.3-24.1 | 700-800 |

| Ø 2.4×22 | 21.2-26.5 | 700-800 |

| Ø 2.6×24 | 27.2-34 | 700-800 |

| Ø 3×20 | 30.1-37.7 | 700-800 |

| Ø 3×25 | 37.7-47.1 | 700-800 |

| Ø 3.2×25 | 42.9-53.6 | 700-800 |

| Ø 3.6×28 | 60.8-76 | 700-800 |

| Shell diameter × shell Length | Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

| Shell diameter × shell Length | Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |