In a high alumina ceramic ball, more than 90% of its main component is the aluminum oxide micro powder. This micro powder is fired with high temperature to form the high alumina ceramic ball. The high alumina ceramic ball is made with more than 1000℃. In the process, the aluminum oxide is of inactivation. Thus, it is different from the activated alumina ball, which can be called the inert alumina ceramic ball.

According to the application, the high alumina ceramic ball can be divided into the high alumina ceramic grinding ball and the inert high alumina padding ball. It is a common issue to distinguish the two kinds of balls. Many enterprises are often asked for the high alumina ball by the clients, but they don’t know what exactly the ceramic ball is. Especially the export companies can not judge of the client’s requirement according to the technical index. Therefore, it is necessary to get to know the two kinds of high alumina ceramic balls.

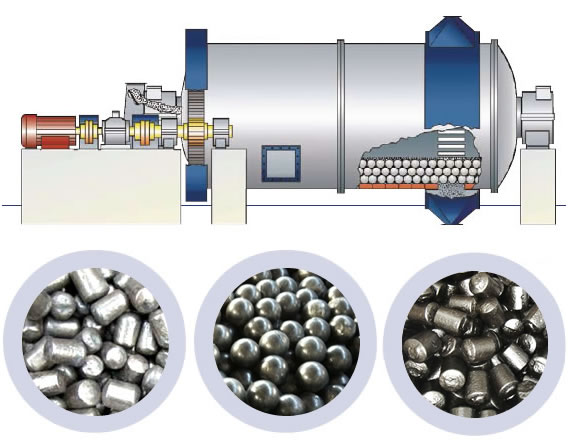

Firstly, in appearance, both of them are pure white. The surface of the high alumina ceramic grinding ball is smooth while that of the high alumina padding ball is rough. The diameter of the high alumina ceramic grinding ball is more than 30mm. It is a equal-diameter one, which is made by being suppressed. Thus, there is an indentation on its surface. However, whatever the size of the padding ball is, all the balls are made by the roll-forming method. Thus, all of them are of the same shape.

Secondly, the applications of them are different. The high alumina ceramic ball is mainly used to grind the material while the high alumina padding ball is used as the cover and support material and the filler of the catalyst inside the reactor. The latter can bear the changes of the temperature in the production process. Its main function is to increase the localities of the gas or liquid and to support and preserve the activated catalyst, which is of low intensity.

Finally, because of the differences of their production process applications, the emphases of their technical indexes are different. Three indexes are important for the high alumina ceramic grinding ball, which are the hardness, density, and abrasion. The abrasion, especially, is directly related to the production cost of the client. However, the high alumina padding ball is mainly used as the propping agent so that what is more important for it are the compression strength, the water absorption, the tolerance, and the sharp variation of the thermal resistance.