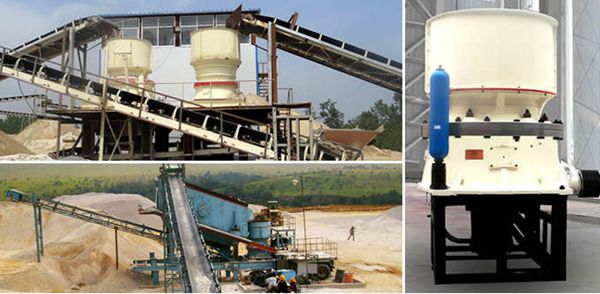

In the material crushing process, as a key equipment in the secondary and fine crushing operation, the cone crusher can directly affect the particle size of the final product and the crushing efficiency in the stone production line. However, the production efficiency of the traditional pressing method is low and with it there is much abrasion. Besides, there is lot of flaky product, which can not meet the national standard and clients’ requirements. But, the lamination crushing principle can not only meet the demand in the secondary and fine crushing process but also can improve the crushing production line. The application of this principle can greatly improve the fine crushing effect of the cone crusher. When it is applied to the mining crushing production, it can directly decrease the feeding size of ore grinders, which can lower the cost.

The lamination crushing principle means the interaction of the material and the toothed plate and the one of the materials between the toothed plate, such as pressing, grinding, etc. In recent years, this principle emerged from foreign countries as a new crushing concept. The classic machine which adopts this principle is the single cylinder cone crusher made by Fote.

According to the expert of Fote, the lamination crushing principle of the single cylinder cone crusher is a kind of alternative crushing method. In the crushing process, the final product’s quality is high and the content of the flaky product is less. Precisely, with the lamination crushing principle, the single cylinder cone crusher has the following advantages:

1. Nice Particle Size of the Final Product

As is known to the clients who are familiar with the standard of the construction aggregate, if there is too much flaky material inside the concrete, the whole strength of the concrete will be affected. Thus, cubic material can meet the national standard. However, the content of the flaky product produced by the traditional crusher is 15% while that of the one produced by the single cylinder cone crusher with the lamination crushing principle is less than 8%, which is beneficial for the sand production for construction.

2. High Crushing Efficiency

Compared with the traditional crushing principle, the lamination crushing principle has higher crushing efficiency mainly because, inside the crushing cavity, many layers of material are forming, which can increase the density of the material inside the crushing cavity in order to crush the material efficiently.

3. Less Abrasion of the Lining Plate

Because the main operation of the single cylinder cone crusher is the lamination crushing process between material and material, the stone material of big block hardly ever hits or wears the lining plate. Therefore, it can greatly decrease the abrasion of the lining plate.