-

Ball Mill

-

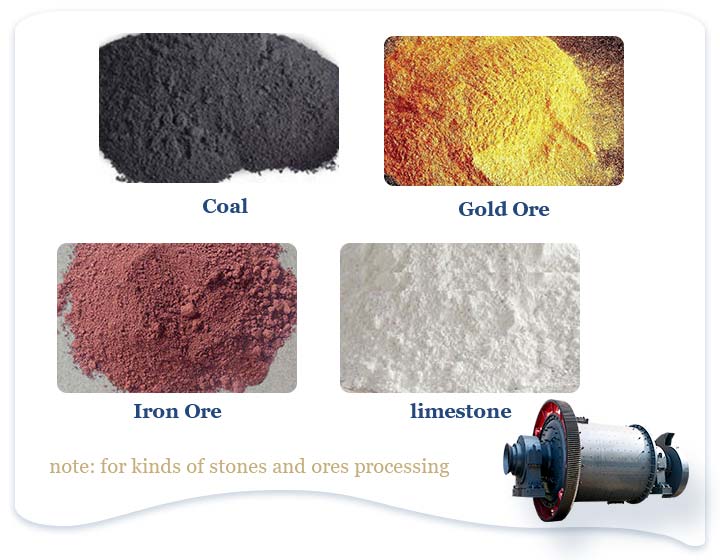

Ball mill, namely ball grinding mill, is widely used for powder grinding of stones and ores, It is widely used for mineral grinding such as iron ore, copper ore, gold ore, cement, lime, slag, silica,bauxite, calcite, etc.

- Email Us: sales@sinoftm.com Enquiry Online

Hot Issues of Ball Mill

Application of Ball Mill

Ball mill, as one kinds of hot sale grinding equipment, is the popular choice for processing metal ores and other minerals. It can be used for wet and dry powder grinding.

| Material | gold ore, copper ore, iron ore, coal, limestone, quartz, etc |

How To Choose Ball Mill

We have full models ball mill for sale, among the various models of ball mill, the best selling ball mill diameter is 1.2-3.2 meter, such as Ф1200×3000, Ф1500×4500, Ф2100×3000,Ф2200×6500, etc. We will provide customized solution for you according to your specific needs. Moreover, we also have ceramic ball mill and rod mill for choice.

Price of Ball Mill

About ball mill price, we will provide 100% factory price and maximum discount for you, no betweener, saving costs.

Technical Parameters

Ball Mill

Ceramic Ball Mill

MBS Rod Mill

| Model | Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Total weight (t) |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | As per process conditions | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | As per process conditions | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | As per process conditions | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 |

| Model | Feeding capacity (t/time) |

Shell rotation speed (r/min) |

Reference motor (kw) |

Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

| Model | Cylinder | Effective Volume (m³) |

Max.Rod Loading (t) |

Speed (r/min) |

Main Motor (KW) |

|

| Diameter (mm) | Length (mm) | |||||

| MBS(Y)-1530 | 1500 | 3000 | 4.5 | 8 | 27 | 90 |

| MBS(Y)-1532 | 1500 | 3200 | 4.8 | 8.5 | 27 | 90 |

| MBS(Y)-1830 | 1830 | 3000 | 6.7 | 14 | 23.7 | 155 |

| MBS(Y)-1832 | 1830 | 3200 | 7.2 | 15 | 23.7 | 155~180 |

| MBS(Y)-2130 | 2100 | 3000 | 8.8 | 18 | 21.4 | 210 |

| MBS(Y)-2132 | 2100 | 3200 | 9.6 | 20 | 21.4 | 210 |

| MBS(Y)-2136 | 2100 | 3600 | 11 | 23 | 21.4 | 245 |

| MBS(Y)-2230 | 2200 | 3000 | 10 | 21 | 19 | 245 |

| MBS(Y)-2236 | 2200 | 3600 | 12 | 25 | 19 | 245 |

| MBS(Y)-2430 | 2400 | 3000 | 12 | 25 | 19 | 280 |

| MBS(Y)-2436 | 2400 | 3600 | 14 | 29 | 19 | 320 |

| MBS(Y)-2730 | 2700 | 3000 | 15.5 | 32.5 | 18.4 | 355 |

| MBS(Y)-2736 | 2700 | 3600 | 18 | 38 | 18.4 | 400 |

| MBS(Y)-2740 | 2700 | 4000 | 20.6 | 43 | 18.4 | 480 |

| MBS(Y)-3040 | 3000 | 4000 | 25.7 | 54 | 17 | 630 |

| MBS(Y)-3230 | 3200 | 3000 | 21 | 44 | 16.4 | 500 |

| MBS(Y)-3245 | 3200 | 4500 | 32 | 67 | 16.4 | 800 |

| MBS(Y)-3642 | 3600 | 4200 | 38 | 79.5 | 15.8 | 1000 |

| MBS(Y)-3645 | 3600 | 4500 | 40.8 | 85 | 15.8 | 1000~1250 |

| MBS(Y)-3650 | 3600 | 5000 | 46 | 96 | 15.8 | 1250 |

| MBS(Y)-3660 | 3600 | 6000 | 54 | 113 | 15.8 | 1400 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Interested in

Cone Crusher?

1.Factory-direct Sale; 100% Factory Price, Saving Costs

2.Three Large Sized Workshops; Stock Available, Fast Delivery (1-4Weeks)

(Note: specific delivery time arranged according to the solution details)

3.Airport Pick Up Service; Invitation Card Available

Why Choose Our Cone Crusher

As the leading stone crusher manufacturer and exporter in China, we open the international market with qualified product and full-service system. We are responsible for each product and each customer all the time.

Company Strength

- Three large sized workshops, strict quality control system.

- Full-service system, such as installation, maintenance, tech support, etc.

- Professional team, customized solution.

- Nearby production site visit

Following is part of our customers and cooperation partners all over the world. Welcome to visit our company.