Capacity:5-500 t/h

Output size:0.84-0.37mm

Applied fields:stone powder grinding

Application:feldspar, calcite, talc, barite, fluorite, rare earth, bentonite, marble, limestone, bauxite,quartz sand, cement clinker, etc.

Chat Online Free Quotation

Within 24hours

Within 24hours

Email reply

Any time

Any time

Factory visit

5-60 days

5-60 days

Transportation time

Any time

Any time

After-sales service

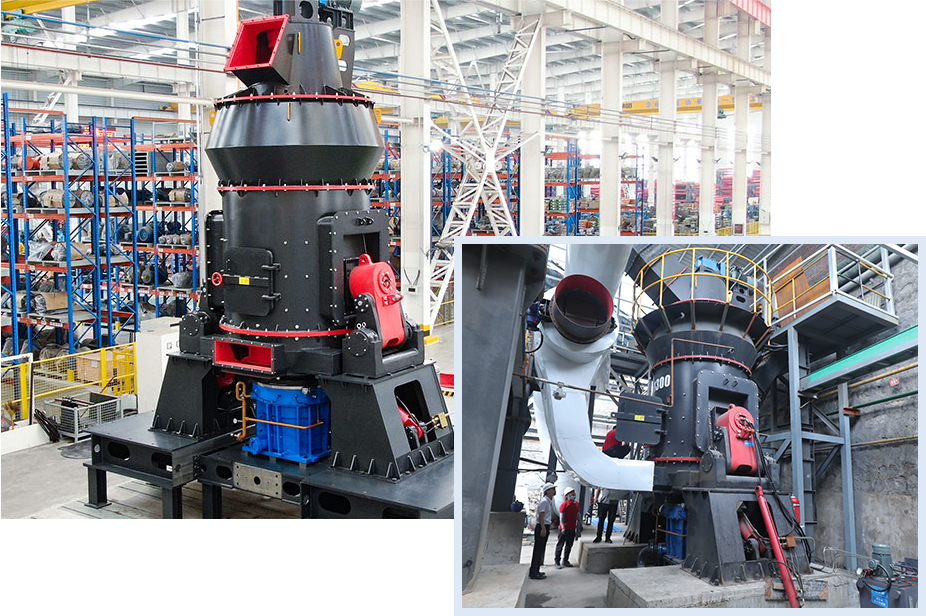

The vertical roller mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical roller mill set crushing, drying, grinding, grading transportation in one, it grind bulk, granular or powdery materials into powdery material as required.

Free Quotation

A vertical roller mill is based on the principle of material bed to grinding materials, which require less energy consumption and promote grinding efficiency. Because the vertical roller mill has a special vertical design, the speed of cutting can be promoted, so that, the working efficiency of the whole vertical roller mill will be high and stable.

The working process of vertical roller mill is closed and produces less noise, there is no dust or wastes or raise dust, ensure the clean working condition and less pollution. In addition, vertical roller mill is required to add certain water into raw materials in the processing, which achieves the goal of save-energy and a clean environment.

The vertical roller mill has simpler structure and processing compared to other types of mill. Less room occupied and outdoor arrangement will directly reduce the investment of plant. Besides, the vertical roller mill has own separator, there is no need of powder concentrator or hoisting equipment.

| Specifications | Capacity(t/h) | The finished product fineness | The raw material moisture | The finished product moisture | Main motor power(kW) |

| HLM1300K | 10-40 | 0.84-0.37mm (20-400 mesh) | ≤15% | ≤1% | 200 |

| HLM1500K | 13-50 | 280 | |||

| HLM1700K | 18-70 | 400 | |||

| HLM1900K | 20-85 | 500 | |||

| HLM2200K | 35-135 | 800-900 | |||

| HLM2400K | 40-160 | 900-1120 | |||

| HLM2800K | 50-200 | 1120-1250 | |||

| HLM3400K | 70-260 | 1800-2000 | |||

| HLM3700K | 90-320 | 2500-2800 |

Note: The grindability (Bond) index of raw materials is less than or equal to 13kw/t

| Specifications | Capacity(t/h) | Specific surface area | The raw material moisture | The finished product moisture | Main motor power(kW) |

| HLM19S | 8-13 | ≥380㎡/kg | ≤5% | ≤1% | 280-315 |

| HLM21S | 11-18 | 400-450 | |||

| HLM24S | 15-20 | 500-560 | |||

| HLM28S | 28-35 | 900-1000 | |||

| HLM35S | 70-80 | 1800-2000 | |||

| HLM42S | 95-110 | 2500-2800 | |||

| HLM46S | 130-150 | 3150-3800 | |||

| HLM53S | 160-200 | 4500-5000 |

Note: The grindability (Bond) index of raw materials is less than or equal to 18kw/t

| Specifications | Capacity(t/h) | Pulverized coal fineness | The raw coal moisture | Pulverized coal moisture | Main motor power(kW) |

| HLM1200M | 6—10 | R0.08=5-15% | ≤15% | ≤1-5% | 110-132 |

| HLM1300M | 10-15 | 160—200 | |||

| HLM1500M | 15—20 | 220—280 | |||

| HLM1700M | 20-30 | 280-355 | |||

| HLM1900M | 26-35 | 355—450 | |||

| HLM2200M | 35-50 | 450—560 | |||

| HLM2400M | 45-55 | 560-710 | |||

| HLM2800M | 60-80 | 900—1120 |

Note:Raw coal HGl≥55

| Specifications | Feed particle size(mm) | Capacity(t/h) | Product fineness | The raw material moisture | Main motor power(kW) |

| HLM1200X | ≤10 | 2-6 | Screen passing rate of 10-40μm 97% | ≤4% | 132 |

| HLM1300X | ≤10 | 3-10 | 220 | ||

| HLM1500X | ≤10 | 4-13 | 315 | ||

| HLM1700X | ≤15 | 7-18 | 450 | ||

| HLM1900X | ≤15 | 8-23 | 560 | ||

| HLM2200X | ≤20 | 13-35 | 800 | ||

| HLM2400X | ≤20 | 15-45 | 1000 |

Note: Mohs hardness grade 4 or below

We provide 100% factory price and maximum discount for you!Our Vertical Roller Mill has been exported to over 160 countries, such as, Pakistan, Egypt, Indonesia, Malaysia, Ethiopia, Nigeria, South Africa, etc. Additionally, if you are new in this industry, we will provide professional suggestions and solutions for you.

Raymond Mill

Raymond mill is a commonly used milling equipment, mainly used for barite,insulation materials with Mohs hardness not more than 9.3 degree, high fine powder processing of nonflammable and non-explosive 280 kinds of materials in mineral and other industrie

Raymond Mill

Raymond mill is a commonly used milling equipment, mainly used for barite,insulation materials with Mohs hardness not more than 9.3 degree, high fine powder processing of nonflammable and non-explosive 280 kinds of materials in mineral and other industrie

Ultrafine Grinding Mill

Ultrafine grinding, also known as ultrafine grinding mill, is a kind of raymond mill. It is widely used in grinding process of ore materials in metallurgy, building materials, chemicals, mining minerals areas.

Ultrafine Grinding Mill

Ultrafine grinding, also known as ultrafine grinding mill, is a kind of raymond mill. It is widely used in grinding process of ore materials in metallurgy, building materials, chemicals, mining minerals areas.

Powder Production Line

The powder production line is made up of main engine,

Powder Production Line

The powder production line is made up of main engine,

Nearly 40 years of production experience, well welcomed by customers from 90+ countries.

Expert design as your order and requirement, with all-around solutions to your problems.

Reasonable plan for grinding procedure and scientific production to help you to gain more profits.

Regular inspection and return visit, and solve your after-sale problems in time.