Granite Crusher

Granite crusher is professionally designed for primary fine crushing of kinds of granite stones. We have types of granite crusher for sale, customized solution for you, meeting different needs.

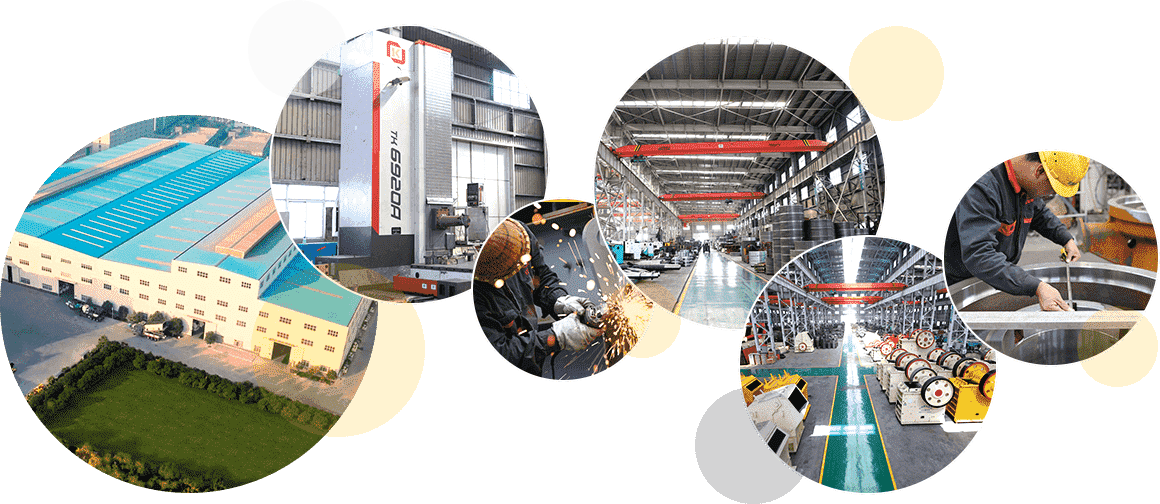

Welcome to visit our actory in China. If not convenient, factory visit online available.

Granite crusher is professionally designed for primary fine crushing of kinds of granite stones. We have types of granite crusher for sale, customized solution for you, meeting different needs.

The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw approaches the fixed jaw, and at the same time, the material is crushed to achieve the purpose of crushing; when the movable jaw descends, the angle between the toggle and the movable jaw becomes smaller. Under the role of pull rod and the spring, the movable jaw leaves the fixed jaw, the crushed materials are discharged from the lower mouth of the crushing cavity. With the continuous rotation of motor and the periodic motion of movable jaw, realizing mass production.

The high-quality steel plate welded frame avoids casting defects, more stable and reliable.

It is made of high wear-resistant gear plates, which has high durability and high performance. The movable jaw assembly is made of high-quality cast steel, more firm and reliable.

The new automatic control system realizes one-button adjustment, reliable and easy to maintain.

The crushing cavity is deep and there is no dead zone, which improves the feeding capacity and output. Its crushing ratio is large and the product size is uniform.

We have small, medium and large granite crusher for sale. Professional team will provide customized solution according to your needs.

Small jaw crusher, impact crusher, small quarry crusher, small power consumption, low costs.

Cone crusher, mobile crusher, large production capacity and high efficiency.

10-20t/h, 20-30t/h, 30-50t/h, etc, usually for small production scale, with low costs.

60-100t/h, 100-150t/h, 250-300t/h, etc, usually for medium and large production scale.

Product price: Price range is about 4000-500,000 dollars. Click for specific price.

Our products have been exported to over 90 countries, such as Philippine, Pakistan, Vietnam, Papua New Guinea, Feiji, Tanzania, Ghana, Cameroon, Kenya, South Africa, Nigeria, Somalia, etc.

As leading manufacturer and supplier in China, we have three large sized modern workshops, more than 260000 square meters, reliable and trustworthy. We are dedicated to be responsible for every procedure, every product and every customer. We provide single equipment and full product plant at 100% factory price for you.

Part ofOur customers and partners around the world

Please fill in the following form, we will send you product details, price and other details as soon as possible.

Copyright © 2026 Henan Fote Heavy Machinery Co.,Ltd. All rights reserved