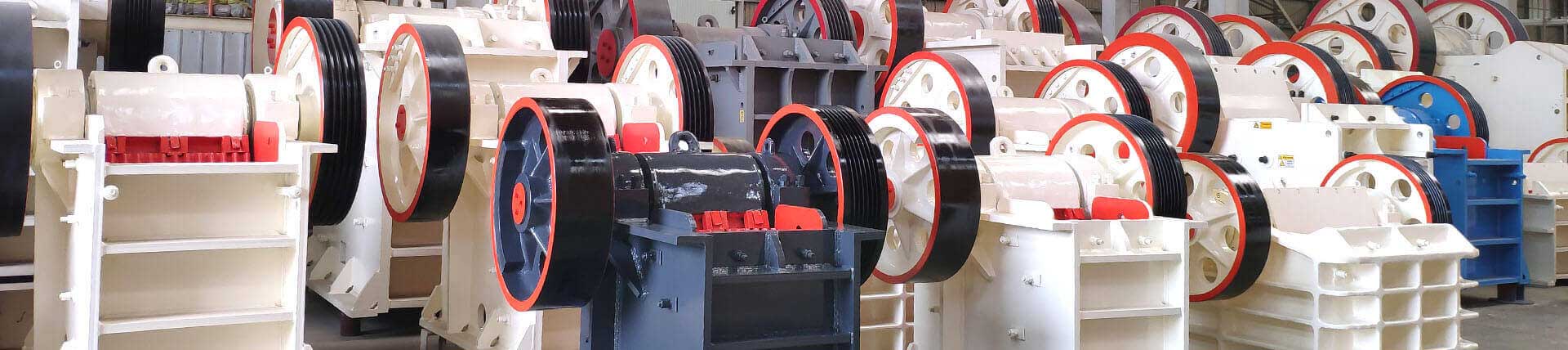

Jaw Crushers

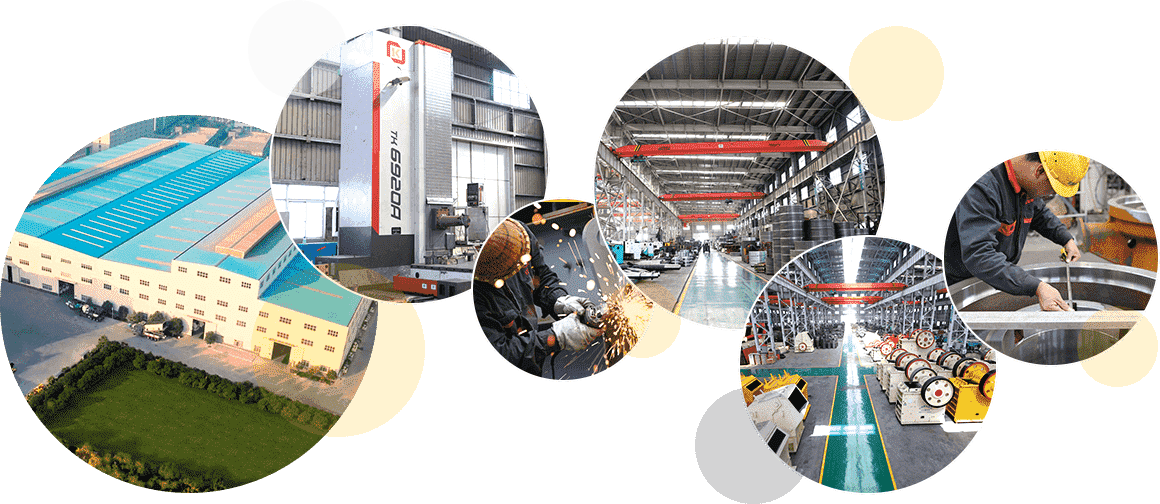

Jaw crusher is a kind of most widely used crushing equipment. With optimized structure and reliable performance, it is well received by customers. It can meet different crushing needs of stones and ores. We have full models jaw crusher for sale.

Processing Materials of Jaw Crusher

It is widely used for primary secondary (first and second stage) crushing of granite, river stone, quarry stone, rock, boulder, gravel, aggregate, basalt, limestone, gold ore, iron ore, chrome ore, etc. Adjustable final size meeting different needs. Following is common final output size.